Ryan Berkley, CAFS, is president of B&B Filters. As a certified air filter specialist by the National Air Filtration Association (NAFA), Ryan’s completed extensive training and testing in the field of air filtration and has a thorough understanding of air filtration principles, technologies and practices. This high level of filter expertise allows Ryan to provide school districts, universities, hospitals, manufacturers, laboratories, research facilities and others customized, quality solutions to their air filtration needs.

Facility Managers: The Backbone of Modern Business Operations

By Ryan Berkley, CAFS

Facility managers are the unsung heroes keeping America's workplaces running smoothly. From Fortune 500 corporate headquarters to healthcare systems, educational institutions and manufacturing plants, these professionals ensure that buildings operate efficiently, safely and cost-effectively while supporting organizational goals.

The role of facility management has evolved dramatically over the past two decades. What once focused primarily on maintenance and janitorial services now encompasses strategic planning, sustainability initiatives, technology integration and employee experience optimization. Today's facility managers are business partners who directly impact productivity, profitability and organizational success.

As businesses increasingly recognize facilities as strategic assets rather than overhead costs, facility managers find themselves at the center of critical decisions affecting everything from energy consumption and regulatory compliance to employee satisfaction and operational efficiency.

The Diverse World of Facility Management

Facility managers work across virtually every industry sector, each presenting unique challenges and requirements:

Manufacturing/industrial facilities require top-notch facility managers who understand industrial processes, safety regulations and production requirements. These environments often involve hazardous materials, specialized ventilation systems and equipment that operates around the clock.

Corporate office buildings require sophisticated HVAC systems, security protocols and technology infrastructure to support knowledge workers. Facility managers must balance energy efficiency with comfort while adapting spaces for hybrid work models and changing business needs.

Healthcare facilities demand specialized expertise in infection control, medical gas systems and regulatory compliance. These environments require precise temperature and humidity control, advanced filtration systems and emergency backup capabilities to protect patient safety and support life-critical operations.

Educational institutions from K-12 schools to major universities present complex challenges including aging infrastructure, limited budgets and diverse space requirements. Facility managers must maintain safe learning environments while optimizing energy usage and coordinating with academic schedules.

Government buildings including federal facilities, courthouses and municipal buildings face unique security requirements, budget constraints and public accountability standards. Facility managers must balance operational efficiency with transparency and compliance requirements.

Retail and hospitality venues depend on facility managers to create inviting customer experiences while maintaining behind-the-scenes operations. These environments require flexible systems that can adapt to varying occupancy levels and seasonal demands.

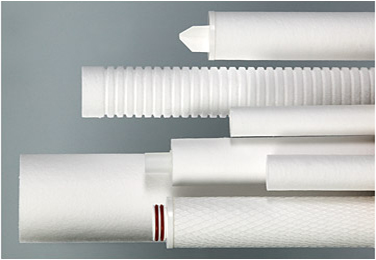

The Critical Role of HVAC and Filtration Systems

For facility managers across all industries, HVAC systems represent one of the largest operational expenses and most critical building components. These systems directly impact energy costs, occupant comfort, indoor air quality and regulatory compliance.

Energy consumption from HVAC systems typically accounts for 40-60% of a building's total energy usage. Inefficient filters force systems to work harder, increasing energy costs and reducing equipment lifespan while failing to deliver optimal performance.

Indoor air quality affects employee productivity, health and satisfaction. Poor filtration can lead to sick building syndrome, increased absenteeism and reduced cognitive performance — issues that facility managers are increasingly held accountable for addressing.

Regulatory compliance in many industries requires documented air quality monitoring and filtration performance. Facility managers must ensure their systems meet or exceed standards for occupational health, environmental protection and industry-specific requirements.

Equipment protection depends on quality filtration that prevents dust, debris and contaminants from damaging expensive HVAC components. Premature equipment failure creates emergency situations that disrupt operations and strain budgets.

Why Facility Managers Need U.S.-Based Filtration Partners They Can Trust

In the high-pressure world of facility management, equipment failures and performance issues reflect directly on professional competence. Smart facility managers understand that reliable filtration represents insurance against costly problems that could damage their reputation and career prospects.

Predictable performance allows facility managers to plan maintenance schedules, budget accurately and avoid emergency situations that create operational chaos. Quality filters deliver consistent airflow and particle removal throughout their service life.

Energy efficiency directly impacts operational budgets and sustainability goals. Premium filters maintain optimal airflow while minimizing energy consumption, helping facility managers demonstrate cost management and environmental stewardship.

Extended equipment life reduces capital expenditure requirements and prevents unexpected replacement costs that can derail facility budgets. Quality filtration protects expensive HVAC components from contamination and premature wear.

Compliance documentation provides the performance data and certifications required for regulatory reporting, audit preparation and quality assurance programs. Reputable filter suppliers provide the documentation facility managers need to demonstrate compliance.

U.S.-sourced filters provide a far more reliable supply chain than depending on overseas filters. prevents stockouts that could force emergency purchases at premium prices or compromise system performance. Established, U.S.-based filter suppliers maintain inventory and delivery capabilities that support predictable operations.

The Hidden Costs of Cutting Corners on Filtration

Experienced facility managers recognize that cheap filters create false economies that ultimately cost more than quality solutions:

- Increased energy bills as systems struggle to maintain airflow through restrictive, clogged filters

- Frequent replacements that increase labor costs and create recurring maintenance disruptions

- Equipment damage from inadequate protection leading to expensive repairs and premature replacement

- Indoor air quality complaints that require investigation, remediation and potential liability exposure

- Emergency situations that force after-hours service calls and premium pricing for urgent replacements

Putting Filter Management on Auto-Pilot

The most successful facility managers implement systematic filter management programs that eliminate guesswork and prevent emergencies:

Scheduled delivery programs ensure filters arrive when needed without requiring constant monitoring and reordering. Automated delivery based on usage patterns and performance data eliminates stockouts and reduces administrative burden.

Performance monitoring through pressure differential measurements and airflow analysis provides objective data for replacement timing rather than arbitrary calendar schedules. This approach optimizes filter life while maintaining system performance.

Inventory management balances carrying costs with availability requirements. Right-sized inventory prevents emergency purchases while minimizing storage space and capital investment.

Budget planning with predictable filter replacement schedules and performance expectations enables accurate forecasting and eliminates budget surprises that can impact other facility priorities.

Documentation systems maintain the performance records and compliance data required for regulatory reporting, warranty claims and operational analysis.

The Smart Choice for Facility Management Success

In today's competitive business environment, facility managers can't afford systems that fail when needed most. Quality filtration from trusted U.S. suppliers provides the reliability, performance and support that enable facility managers to focus on strategic initiatives rather than reactive maintenance.

Energy-efficient, cost-effective filters represent smart investments that deliver measurable returns through reduced energy consumption, extended equipment life and improved operational reliability. When you partner with experienced filter suppliers who understand facility management challenges, you're investing in solutions that protect both your facilities and your professional reputation.

Savvy facility managers understand that cutting-edge filtration technology and reliable service partnerships aren't expenses — they're competitive advantages that enable operational excellence and career success.

Don't let inferior filtration compromise your facility's performance or your professional reputation. Smart facility managers choose quality filters from trusted, U.S.-based partners who understand the stakes.

Looking for customized air filter solutions, faster delivery, or more cost-effective filter options? For personalized recommendations and expert guidance on selecting the right air or water filters, or if you have questions about your air and water filtration challenges, please call (423)-775-2932 or email us.

Share

Similar Posts