Jeffery E. Pizzino, APR, is part of the B&B Filters PR and marketing communications team, bringing decades of experience helping businesses tell their stories in ways that are attention-getting, engaging, and persuasive. Based in Johnson City, Tennessee, Jeff also runs a PR consulting firm and has worked with dozens of organizations across multiple industries as a trusted communications advisor. He holds an MBA in Management from Western International University and a B.A. in Communications with an emphasis in Public Relations from Brigham Young University.

When Precision Matters: How B&B Filters Helped Keep an Automotive Parts Manufacturer Running

By Jeffery E. Pizzino, APR

In the fast-paced world of manufacturing, time is money — and downtime can cost a fortune.

That’s why companies like

OTICS USA don’t just need suppliers. They need reliable partners who respond fast, solve problems creatively, and understand the intricacies of industrial operations.

If they have an urgent need for a commercial filter for their facility in Morristown or Kodak, Tennessee, they need a vendor who can quickly respond.

That’s exactly what they found in B&B Filters.

About OTICS USA

OTICS USA is the American arm of OTICS Corporation, a Japanese manufacturer specializing in high-precision automotive parts. OTICS primarily supplies parts to Toyota and operates two major production facilities encompassing more than 560,000 square feet of manufacturing space.

Their reputation is built on quality, accuracy, and reliability — values shared by B&B Filters.

The Call That Changed the Day

One Tuesday afternoon, B&B Filters President Ryan Berkley was wrapping up his day when he got a call from a maintenance contact at OTICS.

“Hey Ryan, are you in town today?” the voice asked.

Though he wasn’t, Ryan didn’t hesitate.

“They told me they’d recently brought a machining process in-house that they used to outsource,” Ryan recalls. “It involved these really long drill bits that required a very specific, high-pressure water-based filtration system.”

The issue? Their singular filter ran out weeks ahead of schedule, and the replacements were eight weeks out.

A Filter Failure Threatens Production

The team at OTICS had been assured by their Japanese counterparts that the proprietary filters used in the system would last at least three months. But after only about five weeks, their system was already down due to a pressure fault caused by a clogged filter. And with no spare filters on-site or commercial filter suppliers in Morristown they could drive to, they were facing a worst-case scenario: 6–8 weeks of lead time to get replacements from Japan.

“That’s when they called me,” Ryan says. “I told them I could be there in an hour.”

He jumped in his car and headed straight to the facility.

On-Site Insight — And a Surprising Discovery

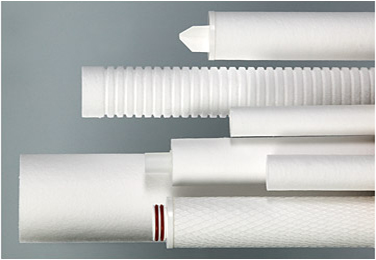

Once at OTICS, Ryan was shown the so-called “proprietary” filter. But as he examined it, a realization hit him: “I’m pretty sure this is just a standard melt-blown filter.”

Melt-blown filters are widely used in water filtration systems. While they’re not designed to capture ultra-fine particles, they’re effective, cost-efficient, and readily available. Despite being told the filter was highly specialized, Ryan had a hunch otherwise.

He took measurements, snapped photos, and sent specs to his manufacturing partners for verification.

Within minutes, it was confirmed: nothing proprietary about it.

From Factory Floor to Next-Day Delivery

Before even leaving OTICS’ parking lot, Ryan placed an order for a case of 50 melt-blown filters to be shipped overnight.

“I had the solution in place before I got home,” he says. “And they paid less than half of what they were expecting — even with expedited shipping.”

The filters arrived the next day, not weeks later. Problem solved.

A Huge Win for OTICS — and a Testament to Partnership

The response from OTICS was immediate and appreciative. “The maintenance team was incredibly grateful,” Ryan remembers. “Even the plant manager was in the room while I was troubleshooting. That tells you how serious the situation was.”

In fact, the plant manager was so impressed, he asked Ryan to quote a new in-line pre-filter housing system to prevent future pressure failures. Ryan explained that he might be able to save them from that added cost too.

“I told them, ‘Let’s wait and see how the new filters perform. I think we’ll avoid future issues without needing a more complex solution.’”

Saving Time and Money — Without Sacrificing Quality

What could have been a costly, weeks-long disruption turned into a one-day hiccup — all thanks to B&B’s fast thinking and even faster action.

Not only did Ryan — being a Tennessee-based filter company — deliver the correct filters the very next day, but he saved the customer up to 60% on costs. More importantly, he helped prevent extended downtime and unnecessary equipment upgrades.

“It wasn’t just about finding a part,” Ryan says. “It was about understanding the system, evaluating their real needs, and using our network to deliver a better solution — quickly.”

Why This Story Matters

For manufacturers, filtration isn’t just about air or water — it’s about operational continuity. Whether you’re cutting precision parts, maintaining cleanrooms, or running HVAC systems in high-volume production environments, every filter plays a role in product quality, employee safety, and process efficiency.

OTICS is a longtime B&B customer — 15 years and counting. They’re a model client, responsive and open to improvement. And their experience illustrates what makes B&B Filters different:

- Speed – Immediate response and same-day problem solving.

- Savings – Solutions that reduce cost without compromising performance.

- Service – A personal, consultative approach to every challenge.

- Supply Chain Confidence – Eliminating long lead times with smart sourcing.

A Partner, Not Just a Vendor

“We’re not here to just drop off boxes,” Ryan says. “We want to know your systems, your goals, and your pain points — so we can help you get ahead of problems, not just react to them.”

This story with OTICS USA is just one example of B&B’s dedication to going above and beyond. And it’s why manufacturers across the Southeast (including in Tennessee cities like Johnson City, Kingsport, Bristol, Elizabethton, Knoxville and others) — and even the Caribbean — turn to B&B Filters for their air and fluid filtration needs.

If you have questions about your air and water filtration challenges — whether it’s finding customized air filter solutions, faster delivery, or more cost-effective options — please call (423)-775-2932 or

email us.

Share

Similar Posts